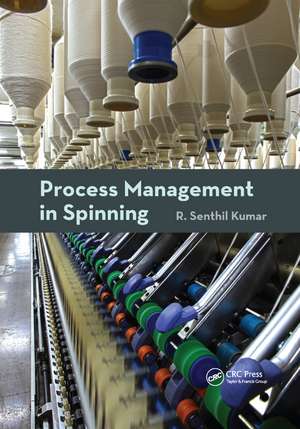

Process Management in Spinning

Autor R. Senthil Kumaren Limba Engleză Paperback – 25 sep 2019

Textile manufacturing is one of the largest industries in the world, second only to agriculture. Spinning covers a prominent segment in textile manufacturing, and this budding industry continues to thrive and grow. Process Management in Spinning considers aspect of process management, and offers insight into the process control procedures and methods of spinning. Focusing on the technology as well as the management of the process, it examines both the economic and technological advancements currently taking place in the spinning industry. This text takes a close look at the advancing technology in manufacturing and process, and product quality control. It provides a basic overview of the subject, and also presents applications of this technology for practicing engineers.

Incorporates Industry-Based, Real-World Examples

The book contains 15 chapters that specifically address the stages of process control, energy management methods, humidification and ventilation systems basics, pollution management, process management tools, productivity, waste control, material handling, and other aspects of spinning mills. It also includes real-time case studies involving typical problems that arise in spinning processes and strategies used to contain them. The author provides a broad outlook on various topics including mixing, winding, raw material and optimizing raw material properties, bale management, yarn engineering systems, processing, and process management systems. He also details the defects associated with each and every process with causes, effects, and control measures. The book addresses process management as it relates to productivity, quality, and costs, as well as process control as it relates to man, machine, and material.

- Provides the scientific method for optimization/optimizing the

| Toate formatele și edițiile | Preț | Express |

|---|---|---|

| Paperback (1) | 489.26 lei 6-8 săpt. | |

| CRC Press – 25 sep 2019 | 489.26 lei 6-8 săpt. | |

| Hardback (1) | 855.50 lei 6-8 săpt. | |

| CRC Press – 23 sep 2014 | 855.50 lei 6-8 săpt. |

Preț: 489.26 lei

Preț vechi: 575.60 lei

-15% Nou

Puncte Express: 734

Preț estimativ în valută:

93.62€ • 98.01$ • 77.46£

93.62€ • 98.01$ • 77.46£

Carte tipărită la comandă

Livrare economică 05-19 aprilie

Preluare comenzi: 021 569.72.76

Specificații

ISBN-13: 9780367378332

ISBN-10: 0367378337

Pagini: 416

Dimensiuni: 178 x 254 x 25 mm

Greutate: 0.45 kg

Ediția:1

Editura: CRC Press

Colecția CRC Press

ISBN-10: 0367378337

Pagini: 416

Dimensiuni: 178 x 254 x 25 mm

Greutate: 0.45 kg

Ediția:1

Editura: CRC Press

Colecția CRC Press

Public țintă

Professional Practice & DevelopmentCuprins

Process Control in Mixing. Process Control in Blow Room. Process Control in Carding. Process Control in Drawing. Process Control in Comber and Its Preparatory. Process Control in Speed Frame. Process Control in Ring Spinning. Process Control in Winding. Process Control in Rotor Spinning. Energy Management in the Spinning Mill. Humidification and Ventilation Management. Pollution Management in Spinning Mill. Process Management Tools. Productivity, Waste Management, and Material Handling. Case Studies. Bibliography. Index.

Notă biografică

R. Senthil Kumar completed his post-graduation in textile engineering from the Indian Institute of Technology (IIT), Delhi, India. He has been an assistant professor in the Department of Textile Technology, Kumaraguru College of Technology, India, since 2009. Kumar has published more than 30 technical and management-related review papers in various international and national journals and has prepared manuals on "non-woven technologies" for international and local textile industries. He has published nearly 200 technical and management-related textile study materials on the online portal (www.scribd.com/sen29iit), and has also authored Textiles for Industrial Applications, which was published by CRC Press in August 2013.

Descriere

This book gives a broad outlook on various aspects of process management from mixing to winding department. Raw material evaluation and selection plays a vital role in process control of spinning. It describes the scientific method adopted to optimize raw material properties. The influence of machine components on process control and quality in each department are covered in a detailed manner with charts and data wherever necessary.