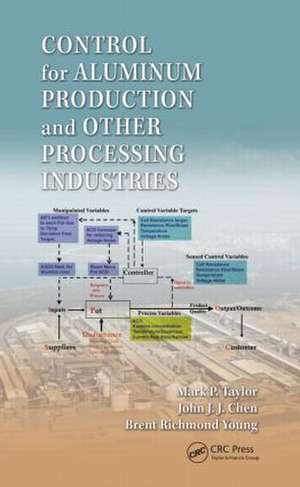

Control for Aluminum Production and Other Processing Industries

Autor Mark P. Taylor, John J. J. Chen, Brent Richmond Youngen Limba Engleză Hardback – 23 oct 2013

Control for Aluminum Production and Other Processing Industries exemplifies new control thinking fused with an understanding of process variability, and how to diagnose abnormalities and their causes in aluminum production plants. Many real life examples in the book demonstrate the importance of human behavior and a scientific, questioning approach in the control of a technologically complex process. Written from the perspective of production staff and management, the book also gives readers a view into the human aspects of accidents and their analogy with failures in control of production.

Production plants regularly experience more control failures than successes and staff must continuously strive to establish stability and control of their process. Through on-the-job experiences of the authors and their industry colleagues, the control experiences described in this book provide readers with a foundation for building their own robust control rationale and a framework for avoidance of plant control problems.

| Toate formatele și edițiile | Preț | Express |

|---|---|---|

| Paperback (1) | 585.27 lei 6-8 săpt. | |

| CRC Press – 29 mar 2017 | 585.27 lei 6-8 săpt. | |

| Hardback (1) | 1383.02 lei 6-8 săpt. | |

| CRC Press – 23 oct 2013 | 1383.02 lei 6-8 săpt. |

Preț: 1383.02 lei

Preț vechi: 1686.60 lei

-18% Nou

Puncte Express: 2075

Preț estimativ în valută:

264.71€ • 275.31$ • 221.83£

264.71€ • 275.31$ • 221.83£

Carte tipărită la comandă

Livrare economică 14-28 martie

Preluare comenzi: 021 569.72.76

Specificații

ISBN-13: 9781466514690

ISBN-10: 1466514698

Pagini: 264

Ilustrații: 93 b/w images and 8 tables

Dimensiuni: 156 x 234 x 20 mm

Greutate: 0.5 kg

Ediția:New.

Editura: CRC Press

Colecția CRC Press

ISBN-10: 1466514698

Pagini: 264

Ilustrații: 93 b/w images and 8 tables

Dimensiuni: 156 x 234 x 20 mm

Greutate: 0.5 kg

Ediția:New.

Editura: CRC Press

Colecția CRC Press

Public țintă

Professional Practice & DevelopmentCuprins

The Importance of Control. A Tour of the Plant. Welcome to Production. Industrial Accidents. A Potline Process Control Failure. Diagnosing Variation in Materials Processing. Understanding Potroom Processes. The Start of a New Culture. Reformulation of Potline Control. People, Process, and Plant. Better Decisions for Control. Accelerating Removal of Variation.

Recenzii

"I enjoyed reading this book and will refer it to others who are new and not so new to aluminium electrolysis. The tales of escape from some of the all too common "sand traps" that persist in this industry are both enlightening and entertaining. But, the real points of reflection shall be upon how to best apply the over-arching principles that are shared in my own never-ending quest for improvement."

––Stephen Lindsay, Alcoa, Inc., USA

"The process control challenges in potline operation are comprehensively covered. The style is a blend of a storyline that will resonate strongly with most potline staff, with the details of the process control methods that can and should be used. This approach highlights that there is a better way! Everyone interested in potline operation, from crew member to general manager to researcher, could benefit from this book."

––Mark Cooksey, CSIRO Enquiries, Australia

––Stephen Lindsay, Alcoa, Inc., USA

"The process control challenges in potline operation are comprehensively covered. The style is a blend of a storyline that will resonate strongly with most potline staff, with the details of the process control methods that can and should be used. This approach highlights that there is a better way! Everyone interested in potline operation, from crew member to general manager to researcher, could benefit from this book."

––Mark Cooksey, CSIRO Enquiries, Australia

Notă biografică

Mark P. Taylor, John J. J. Chen, Brent Richmond Young

Descriere

The book is a synthesis of new control thinking with process variability understanding. The diagnosis of abnormalities and the resolution of their causes are demonstrated for aluminum production plants, and a compendium of symptom/cause/correction responses is included for aluminum plant operators. Most narrated examples also demonstrate the interaction between human behavior and control, requiring a more scientific, questioning approach to the management of production. This approach is drawn from the authors’ more than 25 years of experience, not only in metals plants but also in petrochemical and in food processing plants. Readers get a view into the human aspect of accidents and the problems of production.